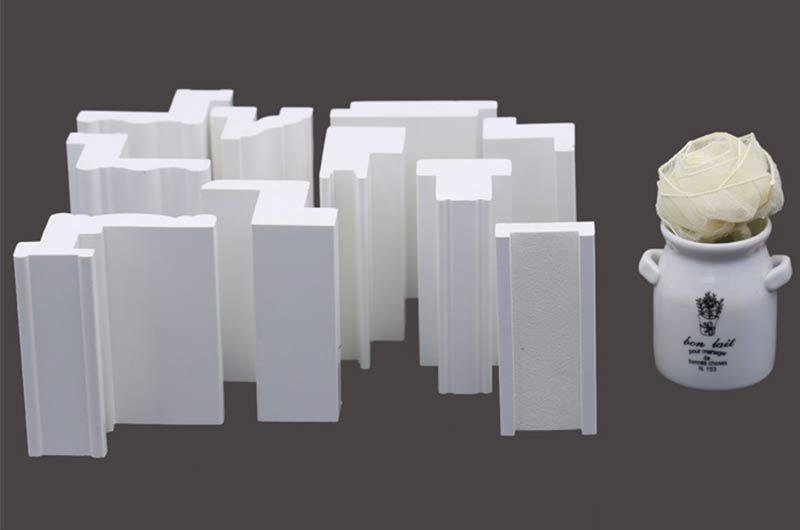

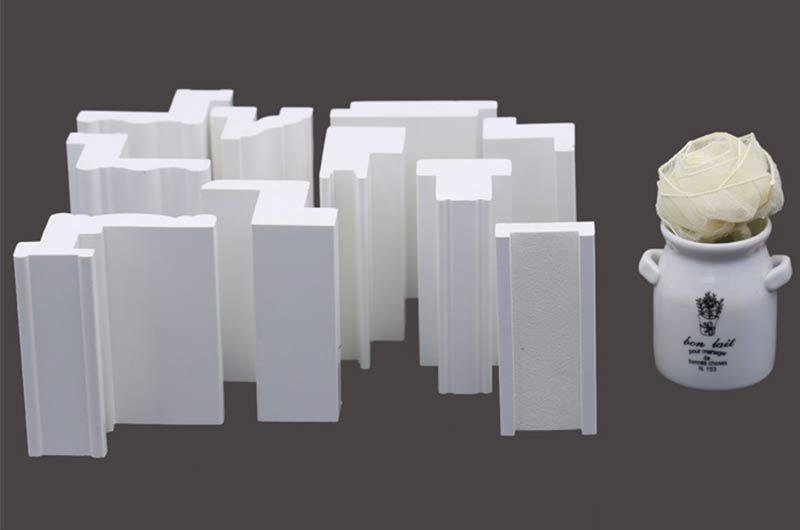

PVC breathable shutter semi-finished product profiles

Addtime:2017-09-28 10:34:55

PVC ventilation shutter semi-finished products are made of solid PVC synthetic material as raw material through high-tech extrusion equipment. It is a product with solid wood properties. It is non-toxic and does not add any lead or mercury. It is the most energy-saving material for manufacturing shutters. General foaming density 0.38-0.8g/cm3, the surface hardness can reach 65-82 Shaw. Compared to PVC free foam board, it has relatively good hardness, smoothness, flatness, strength and nail holding power, and has anti-ultraviolet, coloring performance, heat insulation, sound insulation, acid resistance, alkali resistance, insulation, flame retardant, anticorrosion , anti-mildew, pest control, moisture and other characteristics, can be sawing, planing, nailing, has a good mechanical processing performance, widely used in doors and windows, fences, home, decoration and other fields.

Product advantages:

◆ High strength, long life: Due to the stability of the microporous structure, the product's mechanical properties and compressive strength are guaranteed. The product has good dimensional stability, good pressure resistance and impact resistance, overcomes the defects of ordinary PVC products such as easy breakage and low wood strength, and has a service life of more than 50 years and the same life span as the building.

◆ Sound insulation, flame retardant and heat insulation: The product is formed by countless independent air bubbles, so the sound absorption effect is about 5 times higher than that of ordinary concrete, and the sound insulation coefficient is greater than 45DB. The product is a class A non-flammable inorganic insulation material, fire-resistant limit of more than 3 hours, used in the building, can improve the building's fire performance. Due to its closed porosity of >95%, it has very good thermal insulation properties.

◆ Excellent physical properties: The product is light in volume, small in size, with a density of about 0.68/cm3, and it has unique properties such as vibration resistance, corrosion resistance, moisture resistance, insulation, etc. It can be processed into various specifications according to different purposes, easy to bond , sawing, planing, nailing, cutting and other secondary processing.

◆ Energy-saving and environmental protection: Non-toxic formula and non-liquid additives are adopted. The product is non-volatile and belongs to the green environment-friendly material. To replace wood with wood and save forest resources, the use of 1m3 foam sheet can save 1.7m3 round wood, which is conducive to the maintenance of ecological balance.

Product advantages:

◆ High strength, long life: Due to the stability of the microporous structure, the product's mechanical properties and compressive strength are guaranteed. The product has good dimensional stability, good pressure resistance and impact resistance, overcomes the defects of ordinary PVC products such as easy breakage and low wood strength, and has a service life of more than 50 years and the same life span as the building.

◆ Sound insulation, flame retardant and heat insulation: The product is formed by countless independent air bubbles, so the sound absorption effect is about 5 times higher than that of ordinary concrete, and the sound insulation coefficient is greater than 45DB. The product is a class A non-flammable inorganic insulation material, fire-resistant limit of more than 3 hours, used in the building, can improve the building's fire performance. Due to its closed porosity of >95%, it has very good thermal insulation properties.

◆ Excellent physical properties: The product is light in volume, small in size, with a density of about 0.68/cm3, and it has unique properties such as vibration resistance, corrosion resistance, moisture resistance, insulation, etc. It can be processed into various specifications according to different purposes, easy to bond , sawing, planing, nailing, cutting and other secondary processing.

◆ Energy-saving and environmental protection: Non-toxic formula and non-liquid additives are adopted. The product is non-volatile and belongs to the green environment-friendly material. To replace wood with wood and save forest resources, the use of 1m3 foam sheet can save 1.7m3 round wood, which is conducive to the maintenance of ecological balance.